The North American specialty vehicle industry, a booming market of custom-built ambulances, fire trucks, and other purpose-built vehicles, is on a remarkable growth trajectory. The U.S. alone is expected to see its revenue surge to $33.56 billion by 2030, with a projected growth rate of 3.33%. For manufacturers, this presents a significant opportunity to expand operations, introduce cutting-edge designs, and solidify their place in a vital ecosystem.

Yet, the road ahead isn’t without its turns. Unlike the mass-produced world of automotive manufacturing, this industry operates on a foundation of unique, low-volume orders. Each vehicle is the result of intricate craftsmanship, flexible production methods, and an unwavering commitment to compliance. These very elements, which make the industry so specialized ,also introduce intense pressures on everything from employee and knowledge retention, production costs to lead times and the ultimate ability to scale.

Quick FAQs to get you up to speed

Manufacturers face complex custom builds, strict regulatory requirements, skilled workforce shortages, and supply chain pressures. These challenges affect costs, lead times, and the ability to scale production efficiently.

Variant management tools standardize common steps and adapt workflows for custom options. Operators see only the instructions relevant to their build, making customization efficient and error-free at scale.

Digital work instructions, training modules, and skills matrices capture expertise from veteran staff and make it accessible. This enables faster onboarding, reduces errors, and creates a more adaptable workforce.

They embed compliance checks directly into workflows, automatically log every action, and generate complete audit trails. This reduces manual paperwork, prevents errors, and makes audits faster and more reliable.

Cloud-based, modular platforms like Azumuta offer flexibility without high upfront costs. Manufacturers can start with essentials like digital work instructions or skills tracking and expand as needs grow, keeping the approach cost-effective.

Parts Complexity and Craftsmanship

Every specialty vehicle is essentially a custom project, built in low volumes with numerous bespoke parts and configurations. This variability adds complexity at every turn. Unlike mass-produced cars, specialty vehicles often require manual fabrication and installation. Building them is a craft: one-off or custom orders rarely lend themselves to full automation.

These processes depend on a skilled workforce to fit and finish countless unique parts. Robots and fixed automation thrive on repetition, but in specialty manufacturing tasks often change with each unit. As a result, many vehicles are essentially hand-built, with quality resting on craftsmanship.

The main challenge lies in balancing efficiency with quality. Companies must find ways to streamline and standardize parts of the process to control cost and time, without sacrificing the bespoke features and reliability customers expect. Modular sub-assemblies and digital design tools can reduce variability, but ultimately the human touch remains central.

Regulatory Compliance Pressures

Specialty vehicle manufacturers must comply with multiple layers of rules at once, local, federal, and international standards for safety and emissions. Keeping up is costly and time-consuming, especially as policies and technology drive frequent updates. New lighting features may be required to meet safety mandates, or engines re-engineered to satisfy the latest emissions tier.

For low-volume producers, the burden is heavier. Regulatory costs don’t scale down, and small manufacturers often face compliance expenses more than three times higher than average.

Delays in regulatory guidance can stall innovation. An illustrative case is the U.S. Low-Volume Motor Vehicle Manufacturers Act from 2015 which allowed small-scale replica car manufacturing. Although it aimed to ease compliance, the detailed regulations took seven years to be finalized, leaving manufacturers in the dark until 2022.

Managing compliance requires a proactive approach: investing in expertise, in-line quality testing for areas like crashworthiness and roadability, meticulous documentation, and full traceability for every component.

Skilled Workforce Shortage

While craftsmanship remains central to production, the workforce behind it is under strain. Many experienced workers are reaching retirement age, and there are not enough younger workers entering the trades to replace them. In fact, the US automotive industry faces a significant shortage of skilled labor, with the Bureau of Labor Statistics (BLS) projecting 67,800 annual openings for automotive service technicians through 2033 due to growth and retirements.

When veteran employees leave, they often take with them years of tacit knowledge, from unique build techniques to supplier know-how and troubleshooting skills, much of which was never formally documented. The loss of this tribal knowledge directly affects both productivity and quality.

At the same time, competition for younger operators is intense. Larger manufacturers and even tech companies frequently draw talent away with higher pay or alternative career paths, making it harder for smaller specialty firms to attract and retain skilled workers.

Bringing in new hires is only part of the solution, as training them to the level required for complex builds takes time. During this ramp-up, mistakes are more common and throughput can slow, adding strain to already pressured operations. Retaining seasoned technicians becomes even more important, since they not only maintain output but also serve as mentors who transfer expertise to the next generation.

With nearly 68,000 technician positions opening each year through 2033, the U.S. automotive industry is bracing for a deepening skilled labor shortage, mainly due to retirements and turnover.

Turning Pressure Into Progress: Digital-First Strategies

Specialty vehicle manufacturers need solutions that are cost-effective to deploy, accessible from anywhere via the cloud, and modular enough to address specific pain points. A modern digital platform with these characteristics can tackle key production challenges while fitting into existing operations.

Real-Time Visibility

Instead of waiting for end-of-shift reports, decision-makers and plant managers can view live production data as each custom vehicle moves through assembly. This immediate insight helps manufacturers continually optimize output, control costs, and minimize waste while upholding high quality. With a unified digital dashboard, team leaders and operational managers gain a holistic pulse on operations: which orders are in progress, how long they’ve been at each station, and what’s coming next in the queue. Such clarity turns production into a proactive exercise rather than a reactive one, bottlenecks are identified early and resources are shifted on the fly to keep everything on schedule.

Real-time monitoring alerts teams to issues the moment they arise, allowing immediate intervention before small glitches escalate into big problems. For example, if a calibration is off or a part is delayed, alerts and live data enable rapid adjustments to prevent downtime.

The operational benefits are measurable: manufacturers who implemented live job tracking have cut idle time by over 25% and accelerated job completion by one-third. They’ve also seen higher on-time delivery rates as every stakeholder can see (in real time!) whether production is on track.

Streamlined Compliance

Instead of burdening workers with paperwork and post-process audits, leading firms use digital checklists, sensors, and automatic data capture to ensure every build meets standards by default.

Critical actions, such as torque checks, safety inspections, materials confirmations, are logged automatically, creating an instant audit trail for each vehicle. Compliance with ISO regulations or customer specs becomes part of the workflow, not a last-minute scramble. The payoff is clear: reduced risk of non-compliance and far less time spent preparing audits or chasing missing documentation.

On the floor, workers follow digital prompts that guide both production and mandatory checks, so nothing is overlooked. Deviations, like a torque reading out of spec, are flagged immediately for correction. Managers track compliance via dashboards and intervene early instead of discovering issues after completion.

One manufacturer, for example, moved from manual reporting to a digital platform and saw reporting time drop 60% and data errors drop 90%, greatly improving their audit readiness. By embedding compliance into the production process, companies not only avoid fines and field failures but also instill a culture of “built-in” quality.

Upskilling & Training

Upskilling and training, supported by modern digital tools, keep engineers and operators ahead of the complexity curve. Instead of one-off sessions and knowledge locked in veterans’ heads, companies are turning to continuous learning platforms. A comprehensive skills matrix gives leadership a real-time view of shop floor capabilities, highlighting both gaps to close and strengths to build on.

Digital skills tracking also preserves critical know-how. As senior technicians near retirement, their expertise can be captured through videos, photos, and detailed work instructions, making it part of standard work rather than personal memory. By digitizing tribal knowledge and keeping it accessible, manufacturers ensure hard-won lessons don’t leave with departing employees.

On the shop floor, digital training tools speed up how quickly workers learn. Interactive, step-by-step instructions double as training aids, allowing even less-experienced operators to perform complex tasks reliably from day one. The result is a highly trained, agile workforce ready to handle today’s custom builds and adapt seamlessly to tomorrow’s innovations.

Flexibility at Scale

Since every project can be unique, flexibility must come without chaos. A centralized digital platform connects processes, work instructions, and quality checks, making them easy to adapt. Engineers can update assembly instructions or specifications for a custom order, and changes reach the shop floor in real time. No new manuals need to be printed, and operators aren’t left relying on tribal knowledge.

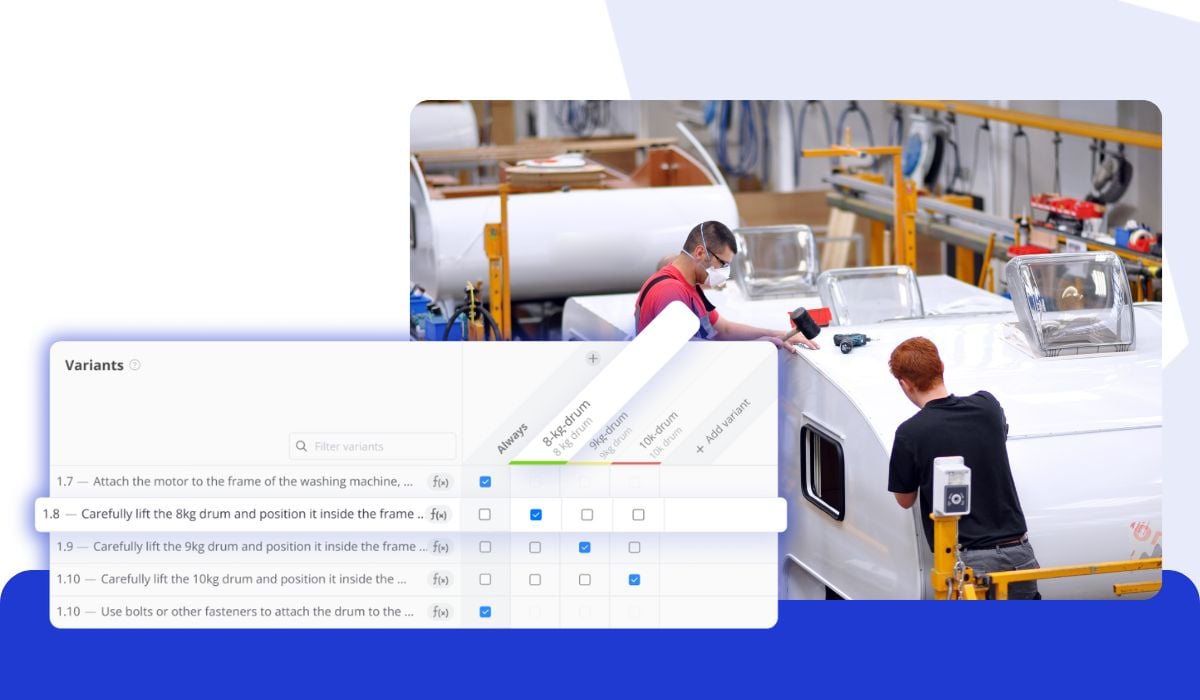

Modern systems support intelligent variant management, allowing multiple product configurations within a single digital instruction set. Common steps are standardized, while variable elements, such as different vehicle options or customer-specific requirements, are managed with simple parameters. This ensures consistency across all builds while cutting redundant paperwork and effort.

If two truck models share 80% of their process, the core instructions are written once and reused; only the 20% that differs is added. Operators then see only the relevant steps for the unit they’re working on, reducing confusion when switching between custom orders.

Supporting functions scale with the same flexibility: each work order links automatically to the correct materials, tools, and skills. Because the platform is cloud-based and connects across departments, improvements like a more efficient assembly method or a new quality check can be rolled out to all product lines instantly. This makes it entirely feasible to meet unique customer requests and last-minute design changes without derailing production.

The Road Ahead

What stands out is that progress doesn’t need to come from sweeping transformations. Incremental moves toward digital visibility, embedded compliance, smarter training, and variant management already deliver measurable impact. These steps help manufacturers safeguard quality, protect institutional knowledge, and stay agile when customers request more complex builds.

The companies that will lead in the years ahead are those that treat these investments not as “extras” but as part of their operational backbone. A cloud-based, modular approach makes this attainable, whether you’re scaling a new production line or fine-tuning an existing shop.

Ultimately, specialty vehicle manufacturing will always rely on skilled hands and careful craftsmanship. But by reinforcing those strengths with the right digital support, manufacturers can strike the balance between tradition and innovation, building vehicles that meet today’s demands while preparing confidently for tomorrow’s.

Create Your First Work Instruction

Try Azumuta today and see how easy it is to create and share work instructions for your manufacturing process.