Cleveland recently attended the MX.0 event, a two-day gathering that brought together industry leaders, economists, and practitioners to discuss the state of manufacturing and where it’s heading. The conversations spanned strategy, digital transformation, people, and performance, but several themes emerged more strongly than others. Instead of treating the notes as a checklist, we’ve pulled out the most relevant and thought-provoking insights and ideas that any manufacturer can reflect on when shaping their own approach.

1. Clarity Before Action

One of the strongest messages from the event was that clarity and alignment must come before execution. Too often, organizations jump into initiatives without ensuring everyone is on the same page, which leads to delays or, worse, derailment. Miscommunication across departments can dilute intent, and downstream groups may unintentionally block progress if they weren’t fully engaged from the start.

The recommendation from speakers was simple but powerful: see the whole vision first. When objectives are clearly defined and every level of the organization understands its role in delivering them, projects are less likely to lose momentum. In other words, aligning decision-making vertically, from the boardroom to the shop floor, isn’t just a nice-to-have, it’s the foundation of sustainable change.

2. Digital Pilots That Stick

Digital transformation was, unsurprisingly, one of the central topics in Cleveland. While most manufacturers recognize the potential of digitization, many remain cautious, weighed down by legacy systems and the sunk costs of past investments. The takeaway here was to reduce the scale of ambition at the outset. Instead of aiming for sweeping transformations, start with a small pilot, perhaps focused on a single machine or process, that can quickly demonstrate value.

But just launching a pilot isn’t enough. A structured period of “hyper-care” following the pilot is key, where teams provide hands-on support, validate KPIs, and work through adoption challenges for months after the initial rollout. These pilots then become proof points for executives and a roadmap for scaling up digital initiatives without overwhelming the organization.

3. People as the Deciding Factor

Another theme woven through multiple discussions was the human side of change. Operators sit at the heart of any manufacturing operation, and if they don’t understand or believe in the benefits of a new initiative, it will struggle to succeed. Communication at the operator level is crucial, not just informing teams about what is happening, but making it clear why it matters and how it affects their day-to-day reality.

As Jonathan Alexander, Global Manufacturing AI & Advanced Analytics Manager at Albemarle Corporation, put it, you need to start with the question operators are really asking: “What’s in it for me?”. If a project doesn’t clearly make their job easier, safer, or more efficient, it will never gain traction where it counts. His advice went beyond messaging. He stressed the importance of involving shop floor employees during the build phase of any initiative: ask which signals matter most, what recurring problems they face, and where they see friction. Their input not only improves implementation quality but also builds ownership that speeds up adoption.

This people-first lens connected directly with another powerful perspective from the event; this time from Susan Helper, economic expert and former senior White House economist. She drew attention to the fact that the challenge in U.S. manufacturing isn’t just a skills gap, but often a wage gap. Many manufacturing roles today pay less than simpler alternatives, making the sector less attractive to current and future workers. Her point was economic and structural. If manufacturers want to attract and retain talent, the work itself needs to evolve.

She outlined a path forward built on three pillars:

- Upskill operators so they can take on more advanced responsibilities and generate higher value per person.

- Align wages with these expanded capabilities, reflecting the real impact and expertise of the workforce.

- Use digitalisation as the enabler, not only to improve productivity, but to equip workers with transferable, future-proof skills that increase their mobility across roles and departments.

At the same time, manufacturers face the dual challenge of driving short-term efficiency with the teams they already have, while also preparing for the future through capability building and better role design. Upskilling programs and thoughtful hiring strategies were highlighted as ways to balance both needs.

But the warning was clear too: when too many change drivers are introduced without clear ownership or communication, organizations risk creating inefficiency instead of progress. For real impact, transformation must feel purposeful and well-guided, not chaotic.

4. Excellence Through Problem-Solving

The sessions on functional excellence offered a refreshing reminder that it’s not about activity for activity’s sake, but about impact. True excellence means solving the right problems and creating value that customers can feel. That starts with asking the right questions: what’s the problem we’re trying to solve, and why does it matter? Without that step, solutions risk being over-engineered or misdirected.

The event highlighted tools like lean analysis and live work-in-progress (WIP) tracking as practical ways to shine a light on inefficiencies and build transparency. The advice was also to refine and improve existing KPIs instead of layering on new ones, ensuring that metrics remain meaningful rather than overwhelming. In essence, excellence is less about ticking boxes and more about continuously sharpening the connection between effort and outcome.

5. Metrics That Matter

Finally, the conversations around metrics emphasized how essential it is to measure what truly counts. Metrics like overall equipment effectiveness (OEE) and operator efficiency remain at the core of operational improvement, but the real power lies in how they’re applied. Small, measurable wins at the shop-floor level help build trust and demonstrate that improvement is possible. These early successes then pave the way for tackling larger challenges.

Panelists also stressed the importance of connecting local efforts to global business needs. For example, reducing downtime by a few percentage points can make a real difference, but it’s equally important to understand where the bigger opportunities lie and plan accordingly. The message was clear: don’t create metrics for the sake of it. Focus on refining the ones that drive meaningful business impact, and ensure they tell a story that everyone in the organization can rally behind.

Closing Thoughts

One clear message from Cleveland was that progress in manufacturing isn’t about chasing the next big initiative, it’s about creating the conditions for momentum. The companies that move forward aren’t necessarily the ones with the most advanced technology or the biggest budgets, but the ones that make decisions with intent, bring people into the process early, and follow through after the kickoff phase.

What stood out across the discussions was a preference for grounded execution: pilots that are small but meaningful, metrics that guide rather than overwhelm, and improvements that build credibility before scaling. Instead of trying to transform everything at once, many speakers pointed to the value of sequencing change, proving impact, reinforcing adoption, and only then widening the scope.

Another takeaway was that operational success depends as much on interpretation as on action. A strong vision is only useful when the people carrying it out understand how their work connects to it. That applies just as much to leadership setting direction as to teams executing on the floor.

In the end, the event didn’t paint transformation as a dramatic leap, but as a series of well-placed steps that compound over time. When clarity, adoption, and measurable impact line up, change doesn’t feel disruptive, it feels like progress that was always meant to happen.

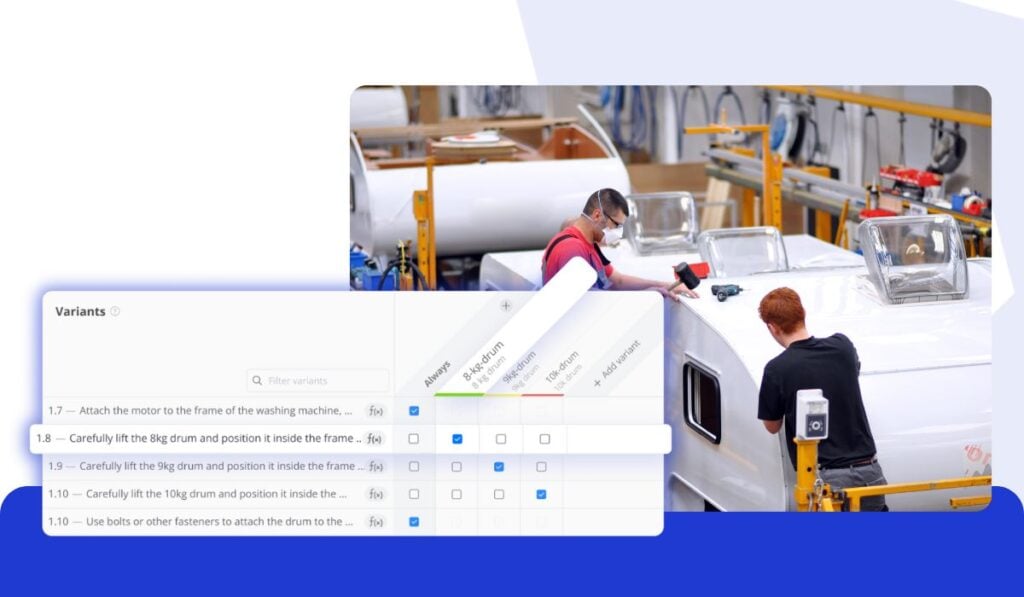

Use Azumuta’s Platform

See how our platform can help streamline data collection, increase productivity, and increase quality assurance with a demo of Azumuta.