Modern manufacturing floors require modern processes. And as technological advances continue to change how products are made, one role remains essential: a process engineer.

Process engineers are tasked with ensuring that the manufacturing process runs smoothly and efficiently. This can involve various activities, from developing new production processes to evaluating existing ones and overseeing their implementation.

It’s also up to a process engineer to ensure the production equipment meets all safety and environmental standards.

Process engineers must consider various factors within the larger manufacturing framework, such as cost-effectiveness, risk management, and quality control. They may also be involved in creating or improving operating systems, sourcing materials, and developing and optimising assembly lines.

As technology evolves, so too does the role of the process engineer — they must stay up to date with industry trends and be able to adapt quickly as processes change. It’s a challenging job, but it can be highly rewarding for those with the right skills and experience.

Learn More About Azumuta’s Digital Work Instructions

Here’s the first step to have a paperless factory

Quick FAQs to get you up to speed

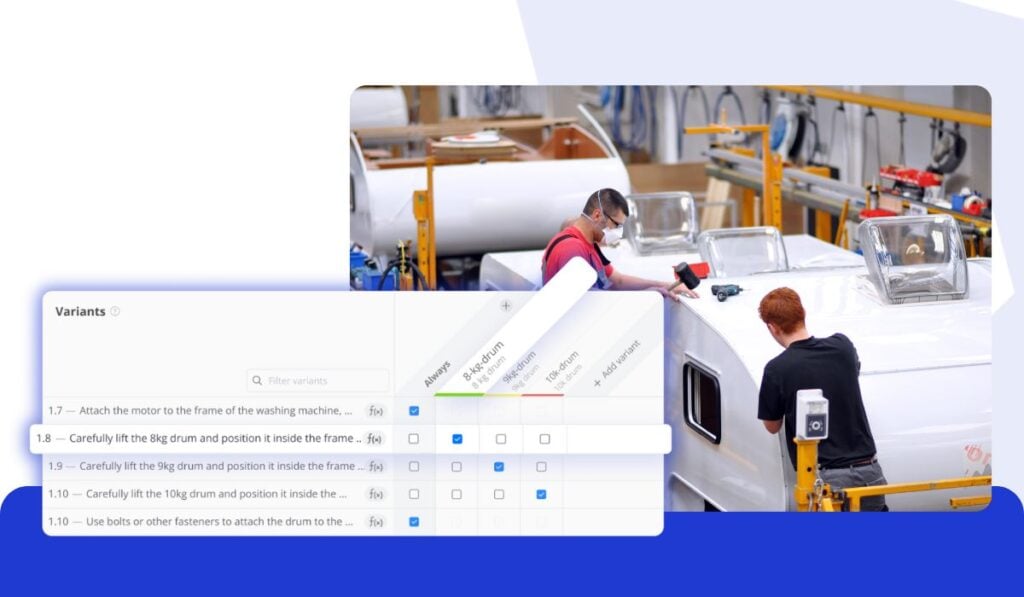

Process engineer work instructions are detailed, step-by-step guides that outline how to execute specific manufacturing tasks efficiently and consistently.

They eliminate process variations, reduce human error, and improve training efficiency, ensuring production quality and compliance.

- Step-by-step procedures – Clear and structured workflow instructions.

- Visual aids – Diagrams, images, and videos for clarity.

- Standardized formatting – Easy-to-follow structure for all operators.

- Compliance integration – Ensures adherence to ISO 9001, OSHA, and industry standards.

Yes. Well-structured work instructions help manufacturers meet industry regulations, safety standards, and quality certifications by ensuring consistency in execution.

Without clear documentation, companies face increased defects, longer training times, and a lack of consistency in production, leading to inefficiencies and higher operational costs.

- Use a structured format with clear headings and numbered steps.

- Incorporate visuals like diagrams and videos for better understanding.

- Keep instructions concise and straightforward—avoid unnecessary complexity.

- Digitize instructions for easy access, real-time updates, and version control.

Collaboration and Cross-functional Teamwork: Process engineers often work closely with other departments, like R&D, Quality, and Production, to achieve the best possible product output. They serve as a technical point of contact and help to coordinate efforts across the organization.

Training: The engineer might be required to train staff on new processes or procedures and ensure they understand the technical nuances of the manufacturing processes.

Project Management: They often lead or participate in cross-functional project teams aimed at implementing new processes, products, or significant changes to existing methods. This includes project planning, resource allocation, timeline management, and execution.

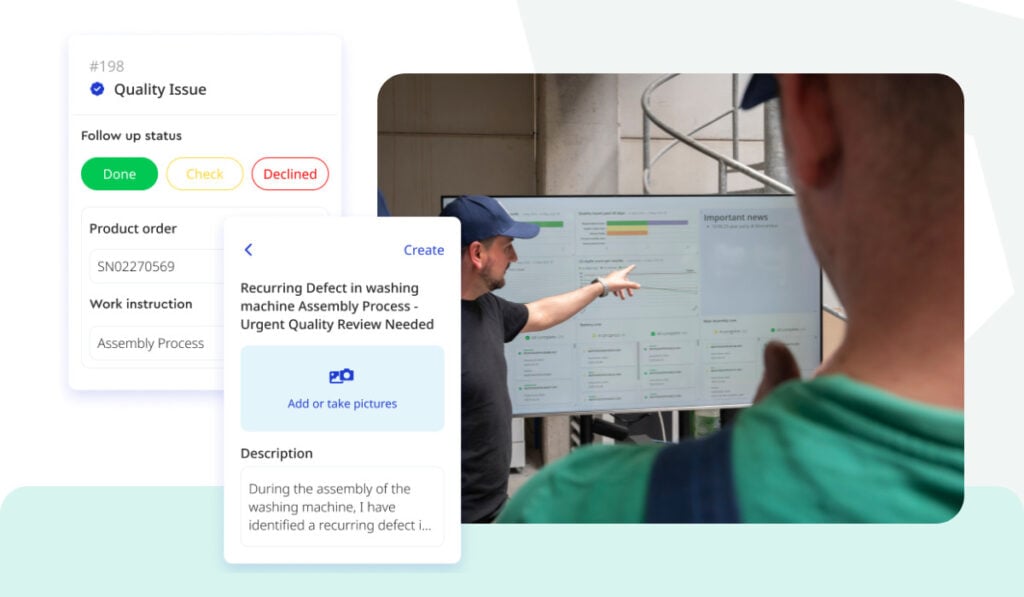

Challenge: Optimizing Production Processes

Finally, process engineers need to ensure that production processes are optimized for performance and cost.

This requires identifying areas of inefficiency, determining root causes, and then implementing measures to improve the overall process. It also involves creating detailed reports on the current state of the operations, using data analysis tools like Six Sigma or Lean Manufacturing methods. When done right, this can lead to significant cost savings and increased efficiency.

Process engineers are constantly looking for ways to increase output and reduce expenses. It’s an ongoing challenge that requires a great deal of technical knowledge and expertise.

Understanding the systems and processes involved in manufacturing is only half the battle – the other half is finding creative solutions that will help optimize production processes.

Learn More About Azumuta’s Digital Work Instructions

Here’s the first step to have a paperless factory