The challenge lies in usability rather than capability. Though MES offers strong technical capabilities, studies show a staggering 75% of manufacturing software initiatives fail to deliver meaningful results. For decades, MES platforms like SAP Manufacturing Integration and Intelligence (MII) / Manufacturing Execution (ME) have been built for IT teams and system integrators rather than operators. As a result, systems feel complex and rigid. Operators still rely on spreadsheets and paper to get the job done, even in today’s Industry 4.0 era.

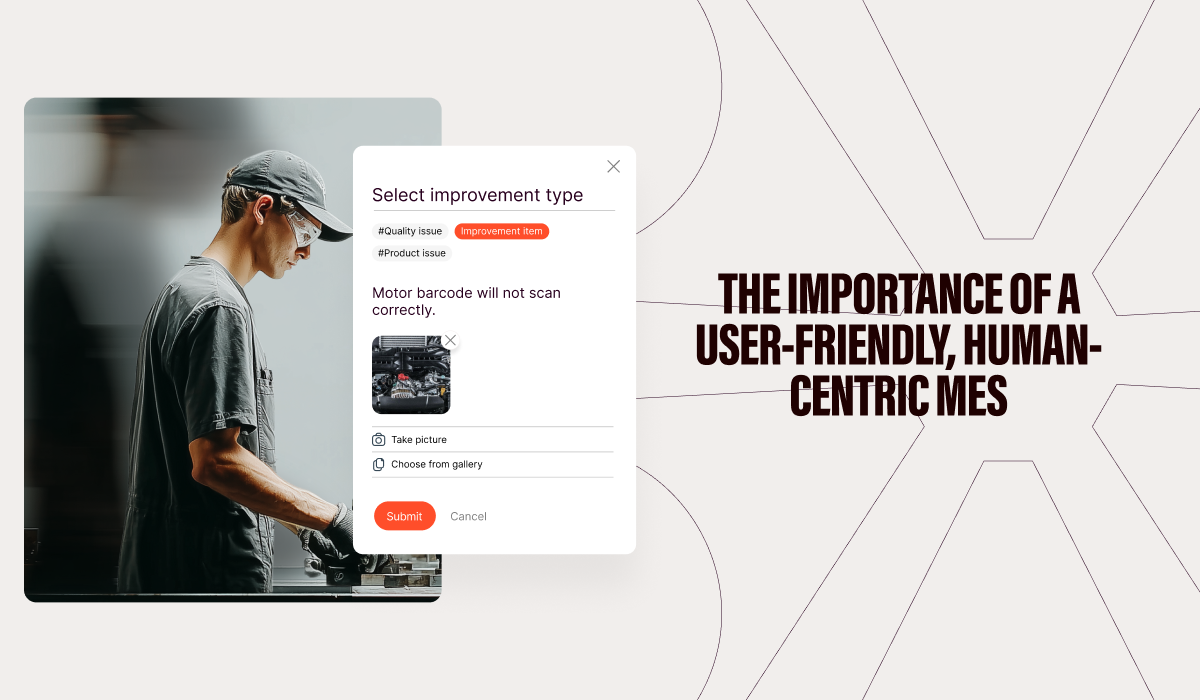

This gap between system capability and human usability is why manufacturers are rethinking the classic MES approach and exploring more human-centric alternatives.

Quick FAQs to get you up to speed

Quick FAQs to get you up to speed

A human-centric MES is a manufacturing execution system designed around operator workflows. It prioritizes usability, clarity, and adaptability without sacrificing compliance or scalability, so people on the shop floor can work efficiently and consistently.

Traditional MES platforms are built for stable processes and IT-led change. Modern manufacturing requires faster adaptation and higher operator engagement with systems that support continuous improvement in real time.

SAP MII often requires extensive customization and long development cycles, leading to high IT dependency. With end-of-life approaching, these limitations increase risk and reduce flexibility for manufacturing teams.

High MES usability improves adoption and data accuracy while supporting compliance. When work feels intuitive for operators, errors decrease and training accelerates. Continuous improvement becomes easier to sustain.

Yes. Modern human-centric MES platforms integrate with ERP and IoT systems through APIs and connectors, allowing manufacturers to avoid lock-in and maintain enterprise-wide consistency.

The Human Factor in Manufacturing Operations

Despite rapid advances in robotics, machines, AI, and industrial IoT, humans remain central to production. Operators make decisions in the moment and adapt to variation, keeping production running at the expected quality level. It’s this engagement that directly influences performance, safety, and regulatory compliance.

However, when MES usability falls short, operational impact includes:

- Delayed or unreliable production data

- Variation in how standard work is carried out

- Longer training and onboarding cycles

- Slower progress in continuous improvement programs

These outcomes stem from systems that are misaligned with how work is performed on the shop floor. Operators then struggle with usability and a lack of speed or relevance. To keep production moving, they create workarounds or disengage from the system. Over time, this behavior is labeled as poor discipline or weak culture. Resistance leads to low system adoption and compliance issues, culminating in digital investments that fail to deliver on value.

Manufacturing software adoption challenges share this same root cause, where tools are used as control layers rather than practical aids. A human-centric MES changes this dynamic. Once the focus shifts to supporting operators, the shortcomings of traditional MES platforms are hard to ignore.

Where Traditional MES Falls Short

Solutions such as MII played an important role in digitizing manufacturing, particularly in regulated and complex environments. Many manufacturers still rely on these platforms that were implemented years ago and expanded incrementally.

Over time, legacy MES challenges have become increasingly visible. These systems are designed with enterprise IT in mind, which is where SAP MII usability issues arise. For example, platforms depend on custom development and require long change cycles with IT support. Usable shop floor interfaces need custom-built components, which makes small usability improvements slow and costly. In addition, user interfaces often prioritize configurability over clarity and carry a high total cost of ownership. Operators may need extensive training to navigate dashboards, transactions, and workflows.

These limitations make MES hard to scale effectively across sites with different operational needs. They also impact operator experience. When even small changes require weeks of development and testing, operational agility takes a hit.

SAP MII End-Of-Life

Adding to these challenges is the end of mainstream maintenance for SAP MII. With an MII feature freeze by 2027 and plans to end support by 2030, manufacturers are forced to make strategic MES decisions: transition to something new or face increasing security, compliance, and operational risk.

SAP Digital Manufacturing Cloud (DMC) offers a cloud-native evolution, but many manufacturers still experience an IT-first design philosophy. Despite its modern architecture, the platform can be complex to implement and operate, and demands heavy transformation effort.

The key takeaway? Power alone is not enough. Usability and speed of change, combined with an operator-first design, matter just as much.

Download the SAP MII end-of-life E-book

This e-book compares SAP’s own successor, SAP DMC, with more modern alternatives that are easier to customize, faster to roll out, and built for frontline usability.

📥 Get the full guide to choosing your next MES strategy.

User-Friendly Design Principles

As manufacturers reassess MII and other legacy MES platforms, they recognize the importance of systems that support how shop floor work is performed.

Human-centric MES solutions like Azumuta address this need by focusing on usability and adaptable configuration. These platforms are defined by a set of design principles that reduce complexity and increase adoption.

Intuitive Work Instructions and Guidance

Modern MES usability in manufacturing starts with clear, digital work instructions. Operators understand tasks at a glance, regardless of language or experience level. Instructions are visual, easy to update, and are mobile-friendly, which helps improve onboarding speed and process consistency.

Empowerment Beyond IT

One of the most important shifts in operator-first manufacturing software is the redistribution of ownership. Modern MES platforms enable operational teams to adapt processes without reliance on centralized IT resources.

Configuration Without Coding

Operations, quality, and engineering teams update workflows and instructions with intuitive no-code configuration tools. This removes the need for custom development or IT tickets, while keeping process changes controlled and auditable.

Faster Response to Change

When production conditions shift or corrective actions are required, updates are implemented within hours. Teams stabilize operations quickly and avoid prolonged disruption caused by slow system change cycles.

Reduced Dependency on System Integrators

When internal teams can manage and evolve their own processes, manufacturers rely less on external system integrators. Process knowledge and data stay inside the organization, strengthening resilience and continuity. This level of empowerment supports continuous improvement and operational excellence by shortening feedback loops and reinforcing accountability.

Integration Without Lock-in

A human-centric MES integrates with ERP systems and IoT platforms through open APIs and connectors. It supports existing ecosystems rather than forcing organizations into a single vendor stack. With this flexibility, manufacturers reduce risk and can support phased digital transformation shop floor initiatives.

Scalable and Resilient by Design

Manufacturers operate in diverse environments. A modern MES supports a range of deployment scenarios from single-site implementations to multi-site rollouts. It also enables shared standards and offline operation in locations where connectivity is limited. The benefit: gradual expansion without forced reimplementation.

Common Misconceptions About MES Modernization

MES modernization is often slowed by assumptions based on earlier generations of manufacturing software. Those assumptions no longer reflect how modern systems are built or used today, and prevent decision-makers from evaluating alternatives objectively.

For example, one common belief is that usability means sacrificing depth or control. In practice, a user-friendly MES can support complex processes. What changes is how complexity is organized and presented to the people doing the work. Another misconception is that operators resist digital tools. What operators actually resist are systems that slow them down or add friction to their work. When MES platforms are intuitive and supportive, adoption follows naturally without enforcement.

Then there is the widespread assumption that replacing a legacy MES requires a full-scale system overhaul. In many cases, manufacturers transition incrementally, integrating human-centric MES capabilities alongside existing systems and expanding over time.

Reconsidering these assumptions makes it easier to evaluate modern MES platforms based on what they can do today, not past experience.

Empowering Operators on the Shop Floor

The value of a human-centric MES shines brightest on the shop floor, where systems support real work under real constraints.

Key scenarios where these platforms excel:

- Standard work enforcement: Operators follow clear, digital instructions that adapt to product or process changes, supporting work without slowing production.

- Quality and compliance: Data is captured at the source with contextual guidance, reducing errors, rework, and audit findings.

- Training and onboarding: New operators become productive faster with guided workflows and visual aids embedded in daily tasks.

- Continuous improvement: Teams can test, refine, and roll out improvements quickly without disrupting production.

One company that illustrates how the right shop floor usability software translates into operational performance gains is Belgian startup Blitz. The family-owned manufacturer produces electric vehicle charging stations in a fast-growing market fuelled by evolving production variants and quality expectations.

As Blitz scaled its operations, the team needed to standardize work instructions. The company wanted to better support operator training and maintain quality without slowing production or increasing IT burden. Existing tools lacked the required flexibility and usability, making it difficult to keep processes aligned with changing products and workflows.

Blitz adopted Azumuta as a human-centric MES layer focused on operator usability. Digital work instructions were introduced at the point of work, giving operators clear, visual guidance that adapted to specific products and assembly steps. Updates could be made quickly by operational teams, reflecting design or process changes immediately on the shop floor. After a two-month implementation period, the company began to see measurable improvements across onboarding, quality, and process standardization.

Time spent onboarding new operators decreased by 80%, falling from roughly one week to a day and a half. By embedding in-line quality checks into daily workflows, Blitz achieved a 98% First Time Right rate and reduced customer complaints to near zero. Operational complexity was reduced, with over 1,600 product configurations consolidated into just three Digital Work Instruction sets.

Together, these improvements gave Blitz greater control over its production processes while maintaining the flexibility needed to scale. The result was a more resilient shop floor, capable of adapting to change without sacrificing quality or efficiency. Perhaps most importantly, Blitz gained the ability to improve continuously without disrupting production. Teams could test process changes and gather feedback from operators. They could also roll out improvements incrementally, supporting growth without introducing rigidity.

Blitz demonstrates how a human-centric MES, built around shop floor usability, gives manufacturers the agility to scale operations while maintaining quality and control.

The Future of Human-Centric MES

Manufacturing is entering a decisive phase. Legacy MES platforms are reaching end-of-life, while expectations around digital transformation continue to rise. Amidst this shift, the human element of production remains central to operational performance.

Reevaluation is no longer optional. Traditional MES approaches have prioritized IT ownership over operator experience, often resulting in low adoption and limited return on investment. Human-centric MES like Azumuta shifts the focus toward clarity and empowerment. These platforms allow manufacturers to respond faster to change and build more resilient digital operations. They also help bridge the gap between humans, machines, robots, and AI without burdening operators with unnecessary cost or rigidity.

MES should serve the people who run production every day. Systems designed to support operators will shape the next generation of manufacturing excellence by adapting to real shop floor needs and enabling a leaner, faster path to Industry 4.0.

Transition to a Human-Centric MES

Learn how manufacturers are moving from SAP MII to an operator-first MES designed for usability, flexibility, and faster change.

Download the eBook →