In a traditional manufacturing environment, supervisors might not discover a production issue until after a shift ends, and by then the details are often buried in spreadsheets. Operators on the floor may flag problems or offer feedback during the shift, but too often there’s no immediate response. These gaps in communication and delayed information mean small issues can snowball into bigger problems before anyone intervenes.

Real-time production visibility and open, two-way communication change that dynamic completely. When teams have immediate access to what’s happening and can discuss it in the moment, they become far more agile in preventing small hiccups from becoming major downtime.

With agility and quality now non-negotiable, trusting yesterday’s reports or gut instinct is no longer enough. Leading manufacturers are prioritizing better visibility and information flow across operations. They’re equipping their workforce with real-time data that’s accessible to everyone and fostering a culture of continuous communication. When everyone can flag issues unfolding live and talk about them right away, they have a chance to react immediately, or even prevent problems before they start. Teams are no longer blindsided by surprises; instead, they anticipate issues and address them proactively.

Modern connected factory systems break down data silos by linking machines, workers, and workflows into one transparent, real-time network. The payoff is a data-driven, collaborative culture where everyone is aligned on a single source of truth and can act instantly to keep production on track.

In this article, we look at how 5 ways for a stronger team communication, supported by real-time insights, creates a more agile and resilient production environment.

5 Ways to Improve Team Communication

Building a real-time, communicative culture takes purposeful practices and tools to get everyone working together seamlessly. Here are 5 practical ways to improve team collaboration and communication on the shop floor:

1. Allow Operator Feedback and Close the Loops

Encouraging operator feedback has long been a cornerstone of successful manufacturing. Take Toyota’s example: their long-standing suggestion box system has proven to be part of their continuous improvement culture for decades, inviting workers to submit ideas on how to improve processes, products, or the work environment. While the intent of such a system is still relevant and valuable, such paper-based solutions have their limitations, as ideas can sit unreviewed for days, and following up takes time, and all in all, fall short in a fast-moving environment.

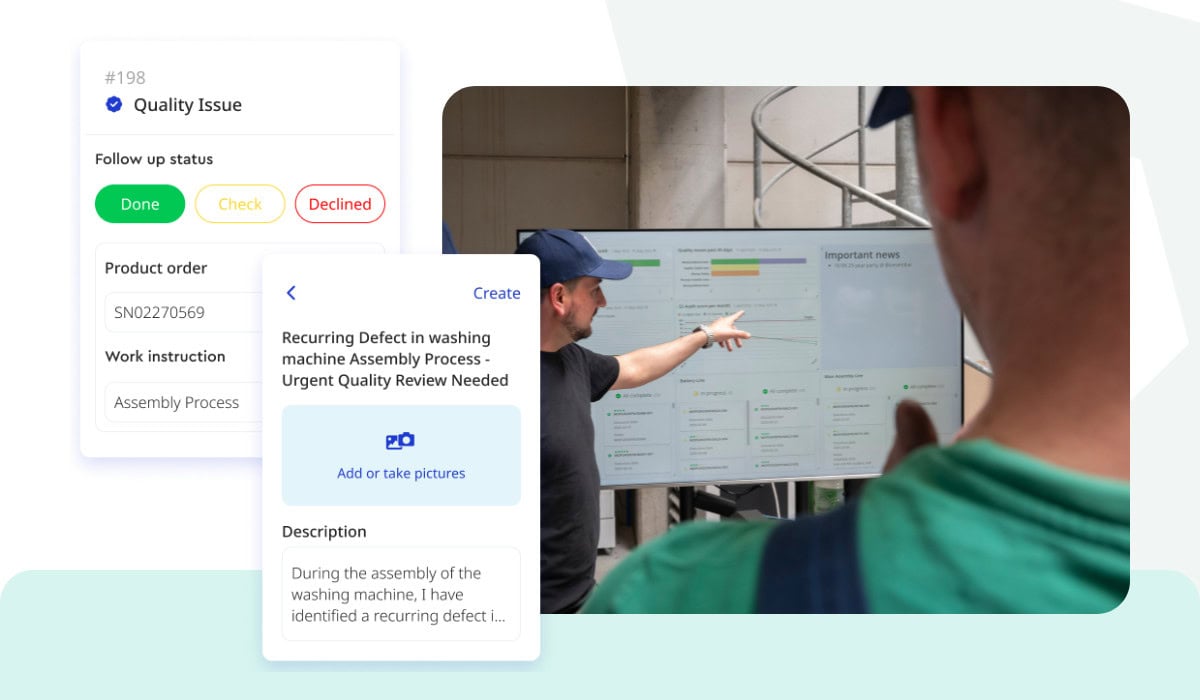

To maximize the value of their insights, you need to provide them with the right tools to do so effectively. Today’s digital tools take that same philosophy and takes it up the digital , supporting in-line feedback. Operators can flag an issue or leave a note directly from their station, without having to leave their post or disrupt their task. This kind of in-the-moment feedback is more immediate, more detailed, and less likely to fall through the cracks. And just as importantly, when responses from supervisors are just as fast, the result is a real two-way loop. Over time, this strengthens trust and ensures that improvements come not just from the top down, but from the floor up.

2. Bridge Language Barriers on the Floor

In multilingual production environments, every operator should have access information in a language they fully understand, whether it’s work instructions, safety guidelines, training content, or real-time updates. This could mean offering translated manuals or using digital systems that allow operators to toggle between language options on-screen.

Artificial intelligence has also elevated automated translations to a whole new level. For example, it’s now possible to upload entire instruction manuals, and specialized software will automatically translate the content into various languages, ensuring accuracy and consistency across all versions. Beyond text, AI-powered tools can even transcribe and translate spoken instructions or video tutorials, making complex procedures accessible to a wider range of operators regardless of their native tongue. This not only improves safety and reduces errors but also fosters a more inclusive and efficient workforce.

3. Share Real-Time Information and Updates

Make real-time information available to everyone on the shop floor and give your operator team access to live production data and updates. When key metrics like output number, quality issues, or audit scores are visible to everyone, keeping them in the loop. This way problems get spotted and addressed fast, not hours later.

Visual management models or dynamic dashboards, displayed on tablets or large screens strategically placed across the shop floor, can present real-time performance data. This ensures operators, supervisors, and managers stay constantly aligned on production status and goals. If a machine slows down, or a quality issue appears, an immediate alert or a clear red flag on the dashboard prompts action right away. This high level of visibility empowers teams to respond rapidly, avoid misunderstandings, and make informed decisions on the spot.

If, for example, a quality issue appears, a notice on the dashboard prompts action right away. This level of visibility helps teams respond fast, avoid misunderstandings, and make decisions on the spot. Instead of waiting for end-of-shift reports, everyone works from the same up-to-date information. Integrating equipment and sensors into a connected platform keeps nothing from slipping through the cracks. And when teams hit their goals? It’s visible instantly, and worth celebrating.

4. Organize Daily Stand-Up Meetings

Implement brief, daily stand-up meetings for each shift to get everyone on the same page. A 10–15 minute team huddle at the start of the day or shift allows supervisors and operators to review current goals, highlight any issues, and coordinate plans. Meeting at the same time each day establishes a routine for open dialogue and ensures that key information is shared face-to-face. This regular in-person communication means concerns are raised immediately and tasks are clearly delegated.

Daily stand-ups help the whole team feel aligned and aware of what’s happening on the shop floor, preventing miscommunications that can occur with only sporadic or one-way updates. Of course, good communication shouldn’t only happen once a day in meetings. After the huddle, you also need ways to keep the conversation going as work unfolds.

5. Set the Tone Early with the Right Training and Onboarding

Effective communication begins the moment a new employee steps onto the shop floor. The initial training and onboarding phase is a critical window to establish clear communication channels and provide the foundational knowledge necessary for success. Starting correctly from the beginning means ensuring that new operators are not only taught what to do but also how to access information, who to communicate with, and how their feedback can contribute.

Instead of overwhelming new hires with thick paper manuals, interactive digital training modules accessible on tablets can guide them through processes step-by-step, complete with images and videos. This ensures consistent, high-quality training across all shifts and locations. Furthermore, onboarding can include immediate access to communication platforms where new operators can quickly ask questions to supervisors or experienced peers, reducing anxiety and accelerating their integration into the team.

E-power’s Succesful Team Communication with Azumuta

One company that exemplifies the benefits of live production visibility and open communication is e‑power, a Belgian manufacturer of sustainable hybrid generators. When e‑power set up a brand-new production hall, they faced a daunting challenge: about 90% of their operators were new to the company, and they were building a pioneering product from scratch. To get this fresh team up to speed and working correctly, e‑power turned to Azumuta’s connected worker platform from day one.

Azumuta’s intuitive, media-rich digital work instructions ensure that even novice operators could follow procedures correctly and consistently.These instructions combined step-by-step guidance with images and video clips directly embedded into the process, so tasks were clear with only needing limited in-person guidance.

To support e-power’s multilingual team, all instructions were made available in English and Dutch. Operators could switch to their preferred language with a single click, helping them understand each task fully and reducing the risk of miscommunication. This combination of clarity, accessibility, and multilingual support was key in getting the new team up to speed quickly and confidently.

At the same time, e‑power enabled real-time feedback on the shop floor: operators could share on-the-spot input through Azumuta’s interface, flagging a difficult step in a work instruction or noting why a defect occurred, and this information would be immediately visible to supervisors and discussed openly. This closed the feedback loop and improved decision-making. Every team member understood the priorities for the day and the status of the line, eliminating miscommunication before it could start.

E‑power has now also established daily power meetings, where team leads and operators gather around a shared KPI dashboard to review progress. In these huddles, up-to-date production data (such as the previous shift’s output, current order statuses, and any quality issues) was instantly visible to all. E‑power’s Plant Manager, Jan Billen, noted the impact of this approach.

Our first-time-right indicator is really improving day by day since we can directly implement the errors and the feedback that we get from the production floor into the system.

By combining clear work instructions, daily stand-up meetings with a shared dashboard, and a closed feedback loop, e‑power kept their new team tightly aligned and able to make better decisions day-to-day. They managed to sustain both speed and quality in their ramp-up process.

E‑power’s experience exemplifies how live insights, when coupled with a culture of communication, can turn a challenging production launch into a success story.