Plant managers know the challenge of scheduling preventive maintenance. Traditionally, machines are serviced at fixed intervals, whether they need it or not. This time-based approach can lead to unnecessary downtime or, conversely, missed maintenance if a machine is overworked between intervals. ut what if the machine itself could signal when it’s time for an audit, and automatically trigger an audit in Azumuta? By connecting machine usage data with Azumuta, maintenance can be scheduled based on real conditions, not the calendar.

By letting machines trigger their own audits and maintenance tasks based on usage, factories can optimize reliability and efficiency. In this article, we explore how to implement machine-triggered audits using Azumuta highlighting its integration with an industrial HMI, such as Siemens WinCC.

We’ll cover how to set up a digital audit in Azumuta, how a machine can initiate and monitor this audit via Azumuta’s API, and why this approach improves uptime, safety, and compliance.

Why Usage-Based Maintenance Beats the Calendar

Traditional preventive maintenance often relies on calendar-based schedules, for example, servicing a machine once a month or once a quarter. While time-based schedules are better than doing nothing, they don’t account for how much the machine actually ran. A machine might produce 5,000 parts in one month or 50,000 parts in the same period.

This is why letting the machine trigger audits based on real usage (e.g. every 10,000 pieces produced) is so valuable. It aligns maintenance with actual wear and tear, rather than arbitrary dates.

Machine-triggered audits based on usage rather than fixed intervals ties maintenance directly to how hard and how often equipment is worked, leading to more reliable performance and efficient production. A usage-based trigger initiates an audit only after the machine reaches a predefined workload threshold.

This approach improves maintenance reliability by reducing unexpected breakdowns and downtime, and it boosts production efficiency since machines are serviced exactly when needed, avoiding both overservicing and neglect.

In addition, it keeps the maintenance schedule aligned with real equipment use, meaning heavily utilized machines get timely attention while lightly used ones aren’t serviced too frequently.

Such usage-based audit triggers can even be automated through the API, allowing maintenance scheduling to dynamically adapt to real-time usage data and seamlessly transition into the next step of scheduling audits via the API.

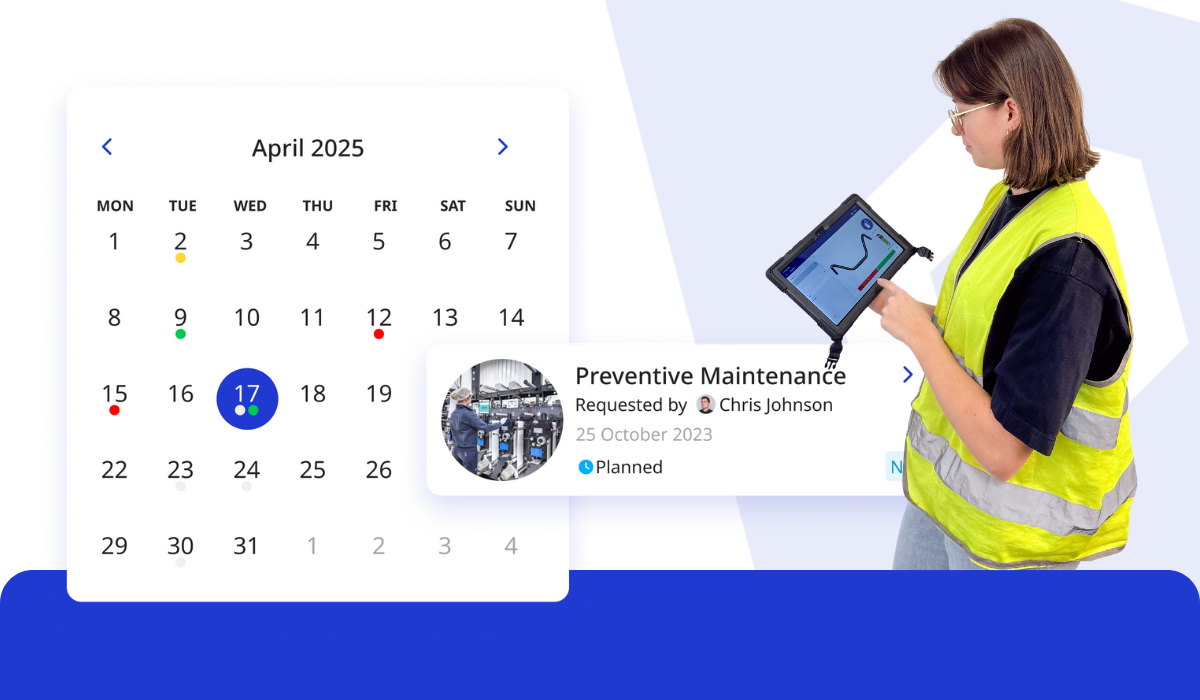

Scheduling Preventive Maintenance Audits Automatically with Azumuta

To move from fixed schedules to usage-based maintenance, your machines need a way to decide, and signal, when it’s time for a preventive maintenance audit. Siemens WinCC collects machine usage data in real time. When integrated with Azumuta, that data becomes actionable.

Using Azumuta’s REST API, WinCC can trigger an audit the moment a machine reaches a defined usage threshold, like every 10,000 parts produced. This integration doesn’t automate the audit itself but connects machine conditions to audit scheduling. The result: audits happen when the machine actually needs them, not when the calendar says so.

Let’s look at how this works in practice.

Integrating External Systems Using Azumuta’s REST API

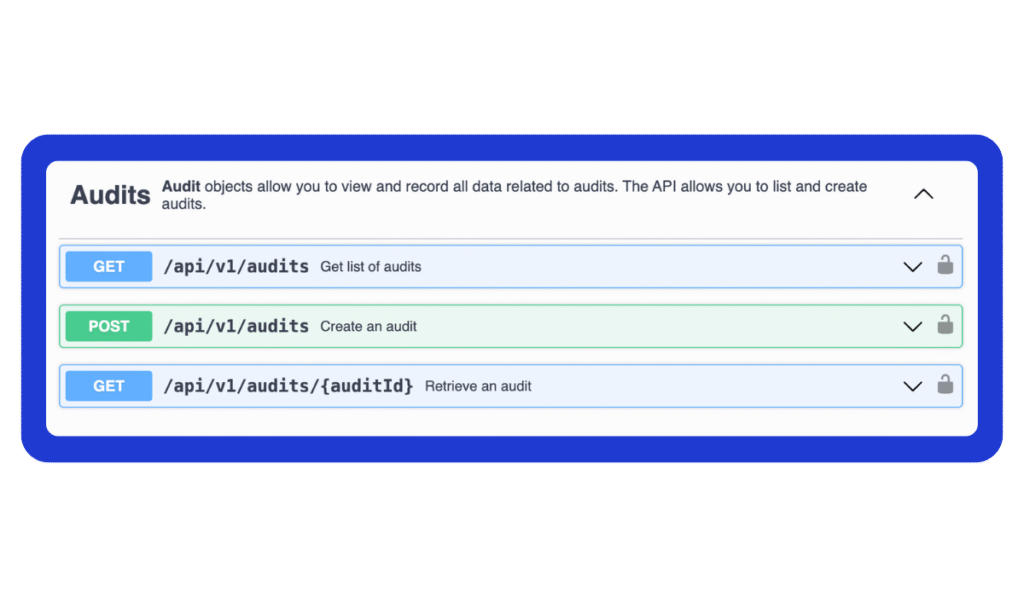

Azumuta’s REST API is built for seamless integration with external systems, such as WinCC or other industrial control platforms, enabling machines and software to communicate directly with the platform. It supports two-way data exchange using standard HTTP methods and response codes, with data returned in JSON format for easy parsing and interoperability.

The API’s predictable structure ensures stable, reliable connections to third-party systems, making it easier to automate processes and share information across platforms. For enhanced usability, an OpenAPI specification is available, allowing technical teams to explore, test, and integrate endpoints efficiently using external tools.

Designed to support flexible, event-driven automation, the API enables external systems to trigger actions in Azumuta and stay synchronized through real-time updates. This architecture simplifies machine-to-system interactions and gives engineers the foundation to build reliable, scalable connections between shop floor controls and digital audit execution, tailored precisely to their production logic.

Scheduling and Monitoring Preventive Maintenance

Connecting the machine’s control system with Azumuta to trigger audits based on real-time usage data, using WinCC, a SCADA/HMI system from Siemens, as an example.

(If you use a different HMI, PLC, or SCADA platform, the concept is similar as long as it can send HTTP requests or otherwise call an API.)

Imagine a CNC machine that should be inspected every 10,000 parts produced. The machine’s PLC is counting parts, and it’s linked to a WinCC system that operators interact with. When the counter hits 10,000, we want the machine to automatically initiate the maintenance audit we set up in Azumuta, and then pause operations until that audit is completed.

WinCC (or the PLC) can be configured to make a REST API call to Azumuta at the moment the threshold is reached. Azumuta provides a RESTful API for external integrations, where external systems can send data to or request data from Azumuta. Using this API, the machine can effectively “talk” to Azumuta.

1.Threshold Reached – Trigger Event

The machine’s counter hits 10,000 pieces. This event can be caught in the PLC or WinCC logic (for example, a script in WinCC could detect the counter value or a PLC memory flag turning true).

2. API POST Request to Azumuta

WinCC then initiates an HTTP POST request to Azumuta’s REST API. This request will include the ID of the audit instruction (the one we created in Azumuta for this maintenance task) and authentication credentials (likely an API key).

Essentially, the machine is telling Azumuta to start a new audit. Azumuta’s API, upon receiving this, will create a new audit instance in the system – just as if a manager had manually scheduled it.

Azumuta’s API is secured with API keys and uses HTTPS for all communication, ensuring the trigger is authorized and safe.

3. Audit Becomes Active in Azumuta

Once the POST request is processed, Azumuta will generate a new audit record (often called an audit instance or session). This record is now visible to the relevant personnel via the Azumuta interface.

For example, the maintenance technician might get a notification on their Azumuta mobile app or see it on their dashboard that “Preventive Maintenance Audit for Machine #12” is now due. The checklist we defined is now ready to be executed by someone.

4. Machine Pauses Production

Simultaneously, the machine should pause or lock operation once it triggers the audit. In our scenario, WinCC can display a message like “Maintenance required: Audit in progress” and prevent further CNC cycles from starting.

This interlock ensures that production doesn’t continue without the required maintenance. It effectively enforces that the audit must be completed for safety and quality reasons.

5. Technician Performs the Audit

A maintenance technician responds to the triggered audit. Using a tablet or workstation, they open Azumuta, see the active audit checklist for the machine, and carry out the steps (checking oil, belts, cleaning, etc., as defined in the checklist). They mark each step as complete, possibly attaching notes or photos as needed. Azumuta records their inputs in real time.

6. Machine Polls for Audit Status

While the audit is underway, the machine’s control system periodically checks if the audit is done. WinCC can do this by sending a GET request to Azumuta’s API at intervals (say, every minute).

The GET request might query the status of that specific audit instance (using the audit ID returned or known from the POST) or filter audits by the identifier or state:

- Filtering by ID: The machine can ask Azumuta for the specific audit record (if it knows the instance ID returned from the creation step). The response would include all details of that audit, including a field like “state” or “completed” = true/false

- Filtering by State: Alternatively, the machine might query something like “list all audits for Machine #12 that are currently overdue”. If the list comes back empty, that could mean the required audit is done (or wasn’t created). More directly, it could query “list audits with status = finished and ID = 12345”. If that returns the audit, then it’s done. If not, it’s still pending.

By filtering by ID or state, the machine can reliably find the audit’s status without confusion.

7. Audit Completion Detected

Once the technician completes all steps and submits the audit, Azumuta updates the status of that audit instance to Finished (and possibly logs who did it and when). The next time the machine polls the API, it sees that the audit’s status is now completed.

8. Machine Resumes Operation

Upon detecting completion, WinCC can automatically release the hold on the machine. For instance, the interlock is removed or the “Start” button becomes active again. A message might display “Maintenance audit completed. Machine unlocked.”

Now the machine can safely resume production, having been properly serviced. The production counter might also be reset or a new cycle begins, and the whole process repeats after the next 10,000 parts.

Managing Digital Audits in Azumuta

Azumuta allows you to create interactive checklists for audits that replace paper forms, making it easy for operators and technicians to complete audits on a tablet or workstation. These checklists can cover a wide range of tasks, such as safety inspections, quality control checks, or machine-specific maintenance routines.

Within Azumuta’s Audits & Digital Checklists, audits can be created from scratch, scheduled manually, or triggered based on specific conditions. Each audit is tracked from creation to completion, ensuring clear visibility into what was checked, when, and by whom. This structured approach helps standardize procedures across teams and equipment, keeping maintenance and quality processes consistent.

All audit data is stored digitally, eliminating paperwork, reducing the chance of human error, and making results immediately accessible. Notes, photos, and signatures are logged in real time and remain available for review at any point. In one case, a manufacturer reduced audit-related data entry time by 60% after switching to Azumuta.

Once your digital audits are in place, they can be triggered directly by machine usage through the API. A machine can pause production, wait for an audit to be completed, and only resume once Azumuta confirms the task is done. This creates a closed-loop system that enforces critical checks, minimizes downtime, and ensures nothing is overlooked.

Get Started with Audits & Digital Checklists

Manage your safety and maintenance audits from a single platform