Behind every finished product lies a series of choices. Some are simple; color, size, or material. Others run much deeper, shaping how the product functions in the hands of its user. A utility vehicle might need a specific cab size and drivetrain to handle rugged terrain, a medical device could require specialized configurations to meet hospital standards, and consumer electronics often demand different plugs or component options depending on the region.

Individually, these choices don’t seem overwhelming. But as they accumulate across product lines, they create a web of possibilities that production teams must track and execute with precision. What drives value for customers often creates new layers of complexity on the shop floor.

The good news: product variants don’t have to be a headache. With the right approach, they can actually become your competitive advantage.

Quick FAQs to get you up to speed

A product variant is a different configuration of the same base product. It could be a truck with a towing package, a medical device with specific software modules, or electronics with different plug types. Variants allow manufacturers to meet diverse customer needs without designing entirely new products.

Each option added to a base product multiplies the number of possible configurations. For example, five simple options on a truck already create 96 possible variants. Adding more colors, engines, or interior packages can push the number into the hundreds or thousands.

Poor variant management can lead to errors in production, rework, scrap, and quality issues. It also drives up training costs, slows onboarding, and makes it harder to keep documentation consistent across all product configurations.

Yes. Azumuta integrates directly with ERP systems, pulling variant specifications automatically into production orders. This eliminates manual selection, reduces the chance of mistakes, and keeps instructions synchronized with order data.

Azumuta uses a grid system to create one master work instruction that covers all variant possibilities. Conditional logic ensures operators only see the steps relevant to the product they are building, avoiding confusion and minimizing errors.

The Exponential Nature of Variant Complexity

Every manufacturing professional understands that variants represent different configurations of the same base product. What many underestimate is how quickly this complexity scales.

Take for example the assembly of a truck with these configuration options:

- Single cab – double cab – crew cab

- Short bed vs. long bed

- 2WD vs. 4WD

- With or without towing package

- Off-road package (skid plates, raised suspension) vs. standard

The mathematics are unforgiving. These five options alone create 96 possible variants. Add complexity, such as different colors, multiple engine options, various interior packages, and you’re managing hundreds or thousands of unique configurations. Each variant potentially requires different procedures, components, quality checks, and documentation.

This exponential growth explains why traditional variant management approaches break down as customization increases. What works for a handful of variants becomes quickly unmanageable at scale.

Critical Operational Challenges You’re Facing

Knowledge Retention in High-Mix Environments

In high-mix, low-volume production, operators encounter specific variant configurations infrequently, sometimes once every few months. Expecting human memory to retain detailed procedural knowledge for dozens of configurations isn’t realistic; it’s setting your team up for failure.

This challenge intensifies with workforce turnover and the need to cross-train operators across multiple product lines. The knowledge burden becomes overwhelming, leading to increased training costs and extended onboarding periods.

Visually Similar Variants with Critical Differences

Perhaps the most dangerous scenario occurs when variants appear nearly identical but require fundamentally different handling. Visual inspection alone cannot reveal these differences, yet they’re crucial for proper assembly, testing, or processing.

These situations create significant risk exposure. A mistake doesn’t just mean rework, it can result in quality failures, safety concerns, or customer returns that damage your reputation and bottom line.

Scalability Limitations of Traditional Methods

Most manufacturers start with simple approaches: separate work instructions for each variant, manual checklists, or operator experience. These methods work initially but become unmanageable as variant counts increase.

Consider the maintenance burden of managing separate instructions for hundreds of variants. A single process change requires updates across dozens of documents. Version control becomes a nightmare, and ensuring consistency across all variants becomes nearly impossible.

Training and Onboarding Bottlenecks

Traditional variant management requires extensive training programs. New employees must learn not only base procedures but also understand how each variant modifies those procedures. This learning curve extends onboarding from days to weeks, significantly impacting productivity and increasing labor costs.

The situation worsens when experienced operators leave, taking variant-specific knowledge with them. Knowledge transfer turns into a critical vulnerability in your operations.

Azumuta’s Integrated Solution Architecture

Azumuta tackles variant chaos with three interconnected ways that work together to make complexity manageable without sacrificing the flexibility you need.

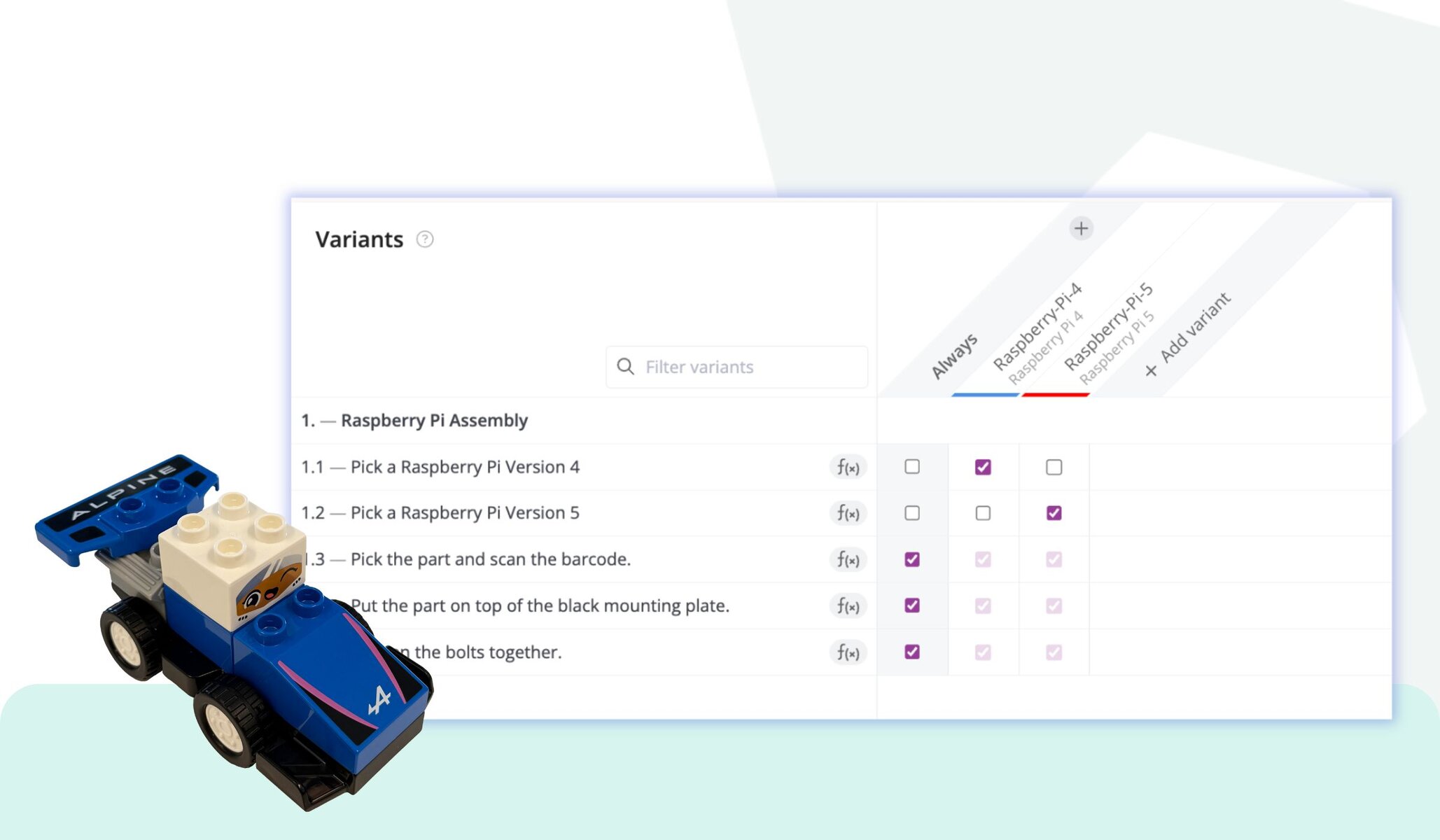

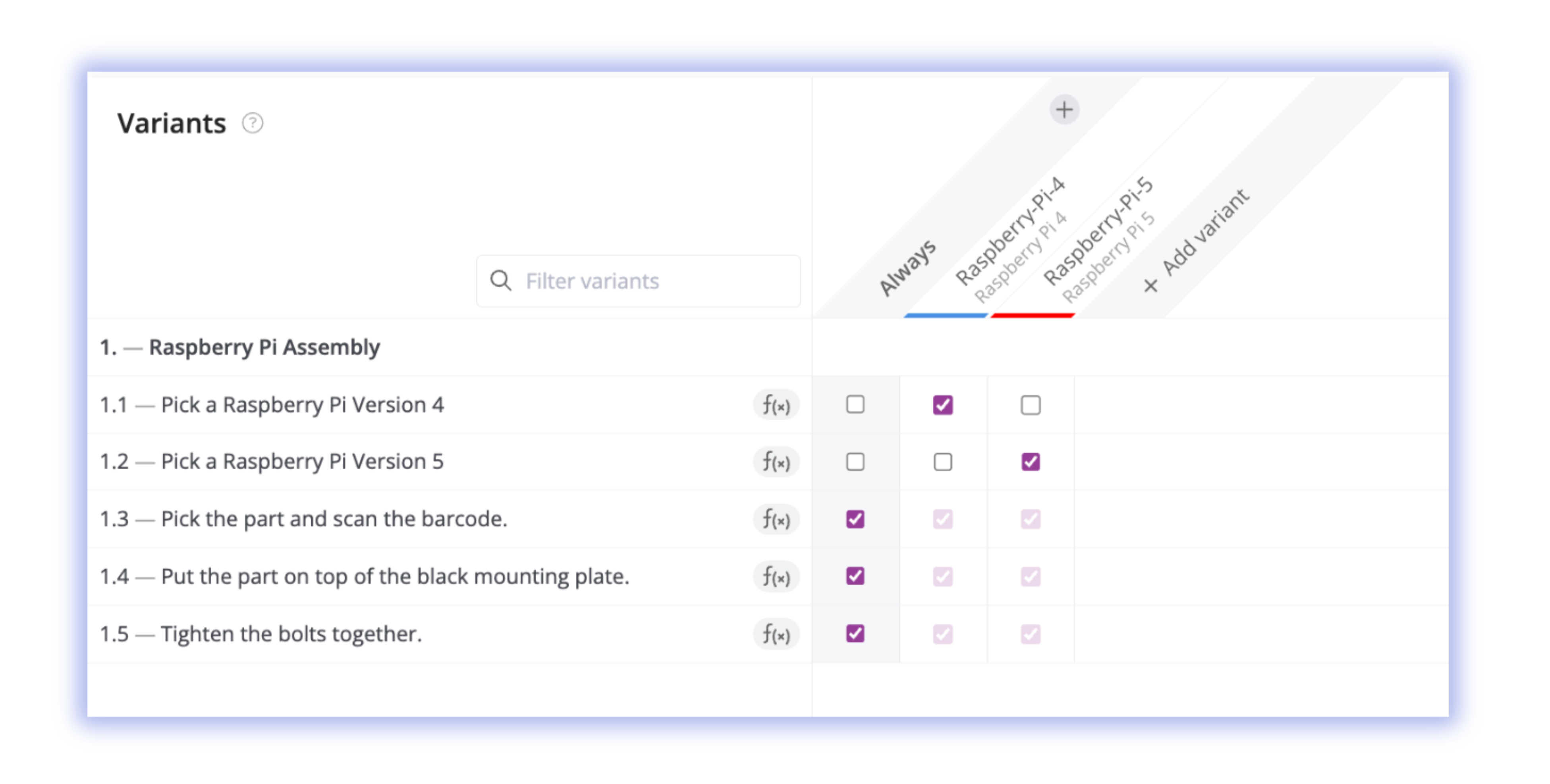

Dynamic Work Instructions with Unified Management

Instead of creating separate instruction documents for each variant, Azumuta uses a grid system that allows manufacturers to build one comprehensive work instruction containing all variant possibilities. Admins define which steps apply to which variants using conditional logic, which then creates rules that determine when specific procedures should be executed.

When a production order starts, the system automatically filters this instruction to show only relevant steps. This means updates to common procedures happen once and apply everywhere they’re needed, while maintaining consistency across all variants. And with that, you get a single view of all variant procedures instead of juggling multiple document sets.

ERP Integration and Automated Configuration

Azumuta connects directly to existing ERP systems to pull variant specifications automatically with each production order. The system maps ERP data fields to variant characteristics defined in the work instructions, creating a seamless handoff from order management to production execution.

This integration eliminates manual variant selection entirely. When an order enters production, Azumuta reads the configuration directly from ERP data and determines exactly which procedures apply to that specific unit. Operators don’t need to look up specifications or decode part numbers, the system handles the translation automatically and keeps everything synchronized as orders flow through the facility.

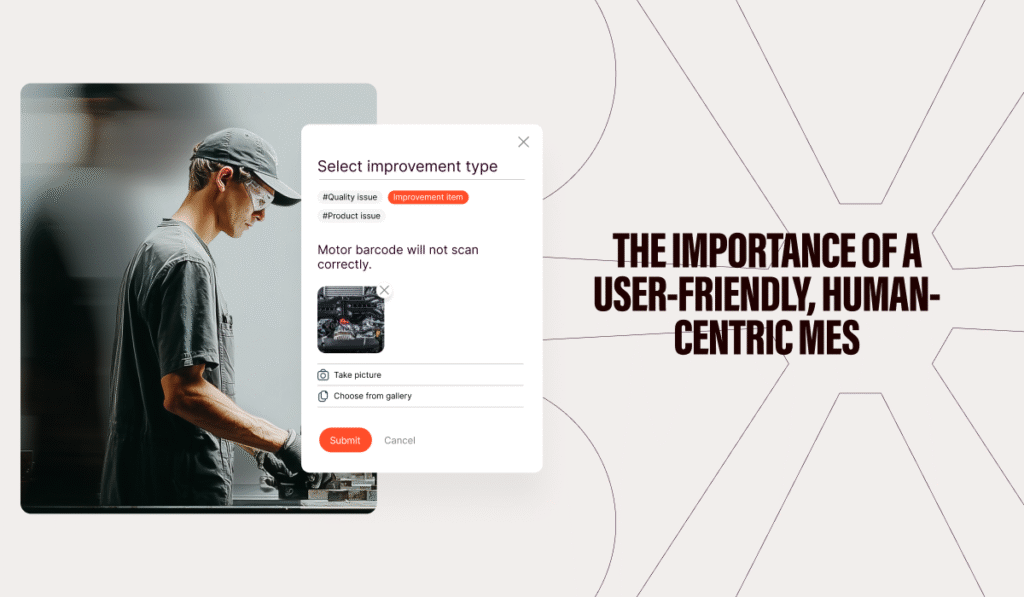

Operator-Centric Interface Design

The shop floor interface shows operators the steps that apply to their current production order. If they’re building a red car with a towing package, they’ll see instructions for towing equipment installation and red paint quality checks, but not procedures for other colors or equipment options.

This focused presentation reduces the mental effort required to process instructions and eliminates the risk of following incorrect procedures. New operators can become productive more quickly since they’re not overwhelmed with information about variants they’re not currently building, and execution speeds up since there’s no need to mentally filter through irrelevant steps.

Training new people on rare variants no longer takes weeks; with guided instructions, they can handle complexity in just a few hours.

Industry-Specific Applications and Benefits

High-mix, low-volume environments are especially vulnerable to variant complexity. Electronics, machinery, and medical devices often come in numerous configurations shaped by regional standards, engineering updates, or customer-specific requests. Managing these differences at scale can quickly overwhelm traditional processes. The same pressures are seen in special vehicle manufacturing, where emergency response fleets, utility vehicles, and defense applications all demand tailored configurations, from pump and ladder systems in fire trucks to specialized equipment in military transport. In both cases, the ability to adapt instructions dynamically and ensure operators always follow the correct procedures is critical for maintaining quality and avoiding costly errors.

Making Variants Work for You

Many manufacturers struggle with variant management, weighed down by endless documentation updates, lengthy training programs, and the risk of errors. But those who approach it strategically turn complexity into a strength. They can confidently take on customer requests that others hesitate over, train new operators in hours rather than weeks, and keep procedures consistent with a single update instead of chasing down dozens of separate documents.

Azumuta makes this shift possible by centralizing variant instructions, connecting seamlessly with ERP systems, and tailoring the operator view to each production order. What was once a constant source of inefficiency becomes a controlled, scalable process that strengthens both quality and responsiveness.

Variant complexity doesn’t have to limit growth. With the right system in place, it becomes a foundation for competitive advantage.

Create Your First Work Instruction

Try Azumuta today and see how easy it is to create and share work instructions for your manufacturing process.