Quick FAQs to get you up to speed

A preventive maintenance checklist is a structured list of routine inspections, servicing tasks, and checks to ensure equipment operates efficiently and safely.

It prevents unexpected equipment failures, reducing downtime, repair costs, and safety risks.

- Visual inspections – Check for leaks, corrosion, or wear.

- Lubrication & cleaning – Ensure moving parts operate smoothly.

- Calibration & alignment – Verify accuracy of machines and tools.

- Component replacements – Swap out worn-out parts before failure.

- Software & firmware updates – Keep digital systems running efficiently.

Yes. Preventive maintenance helps ensure compliance with ISO 9001, OSHA safety standards, and industry-specific maintenance regulations.

Without preventive maintenance, manufacturers risk higher repair costs, increased downtime, safety hazards, and decreased equipment lifespan.

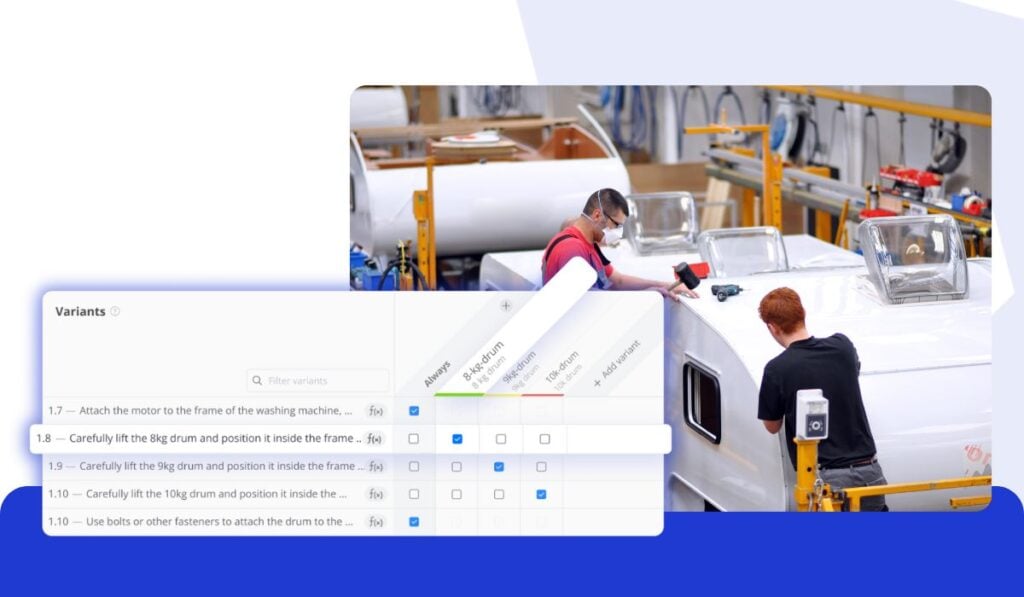

- Customize checklists based on equipment type and usage.

- Schedule routine inspections to prevent emergency breakdowns.

- Use digital tracking systems to log maintenance history.

- Train employees to follow standardized maintenance procedures.

Within the manufacturing industry, maintenance and repair are essential for efficient operation. And while some repairs are inevitable, the goal of any maintenance program should be to reduce downtime and prevent any costly unplanned emergency repair work.

Yet many firms implement reactive maintenance, stepping in to handle issues only when they arise. Dealing with problems only when they occur can be problematic. According to the data, unscheduled downtime mainly occurs due to unsuitable equipment (44%). Additionally, 16% of downtime is attributed to operator error – or not knowing when to perform preventative maintenance.

It doesn’t have to be this way. By scheduling regular preventative maintenance checks, you can proactively identify potential problems before they arise and become costly repairs. This is where a well-crafted preventative maintenance checklist comes in handy.

A well-designed preventative maintenance checklist – and a well-trained maintenance team to implement it – can help you keep your facility or equipment running at peak efficiency and extend its life cycle.

What should preventative maintenance checklists include, and how can you measure the effectiveness of your preventative maintenance program? Let’s take a closer look.

Get Started with Audits & Digital Checklists

Manage your safety and maintenance audits from a single platform

Learn More About Azumuta’s Audits & Digital Checklists

Here’s the first step to have a paperless factory

Step 7: Create Your Preventative Maintenance Schedule

Using the information gathered in the previous steps, create a maintenance schedule. This should include the frequency of each maintenance task, who is responsible for performing it, and the estimated time it will take.

Be sure to allow for flexibility in your schedule to accommodate unexpected repairs or breakdowns – even the most carefully planned maintenance schedule can be thrown off by an unforeseen problem.

Step 8: Implement, Monitor, & Adapt

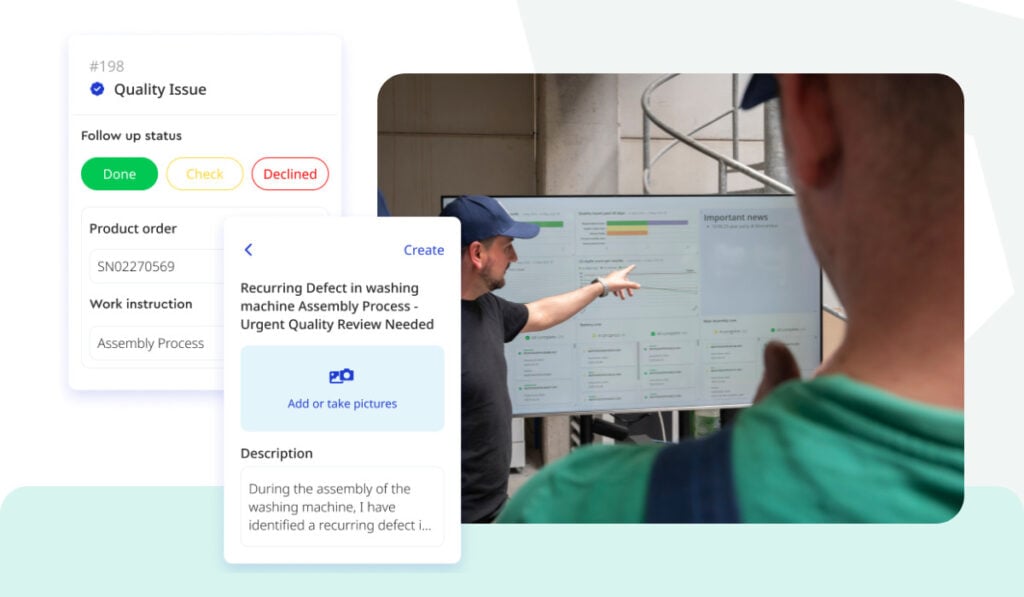

After creating your preventative maintenance checklist, it’s time to implement it!

Monitor your program closely, especially in the early stages, to ensure tasks are completed as planned and effectively prevent equipment failures. As you see how your maintenance plan is performing, you can adjust it as needed to ensure maximum efficiency and success.

For example, if you begin to notice a significant decrease in the number of breakdowns, you may be able to reduce the frequency of specific maintenance tasks. On the other hand, if your preventative maintenance program isn’t having its intended effect, don’t hesitate to add additional tasks or increase the frequency of existing ones.