The Ghent-based software company helps manufacturers turn frontline know-how into connected, digital processes, bridging the gap between people and technology on the shop floor.

Ghent, November 13, 2025 – Manufacturers worldwide still rely on paper, spreadsheets, and fragmented systems to run critical shop floor processes. Azumuta, the operator-centric manufacturing software from Ghent, Belgium, is changing that.

The company has now raised €8M in Series A funding to expand internationally and accelerate development of its platform for AI-supported digital work instructions, quality control, and workforce training and skill tracking. The round was led by Keen Venture Partners, with participation from Capricorn Partners, and returning investors PMV, Angelwise and Dirk Vermunicht.

The fresh capital will be used to grow Azumuta’s team, enter new markets, and build out features that help manufacturers streamline operations, improve quality, and empower their workforce.

“Every week we meet manufacturers still managing critical processes on paper or spreadsheets,” says Batist Leman, founder and CEO of Azumuta. “There’s no lack of ambition, just a need for technology built for real production environments. We built Azumuta to close that gap, helping factories digitalize in a way that actually fits how they operate. This round lets us accelerate that mission and lead the way toward more intuitive, human-centered shop floor technology.”

Digitizing Shop Floor Know-How

What started in 2016 as a digital work instruction tool has evolved into a comprehensive shop floor platform used by about 100 manufacturers worldwide. By combining work instructions, audits, training, and quality control in one connected system, Azumuta gives manufacturers a central hub for operational knowledge.

The results are tangible: users report up to a 50% reduction in administrative time spent creating work instructions and 60% fewer quality complaints caused by human errors.

At Atlas Copco, Toyota Motor Europe, and Sioux Technologies, Azumuta is already part of daily operations.

“Operational efficiency is one of our key priorities,” says Johan Dom, Vice President of Engineering at Atlas Copco. “As we work toward becoming a factory of the future, digital transformation is essential. That’s where Azumuta plays a crucial role. It’s not just an information tool; it’s how we train, learn, and continuously improve on the shop floor.”

According to Robert Verwaayen, General Partner at Keen Venture Partners, this shift fits into a broader trend reshaping the manufacturing industry:

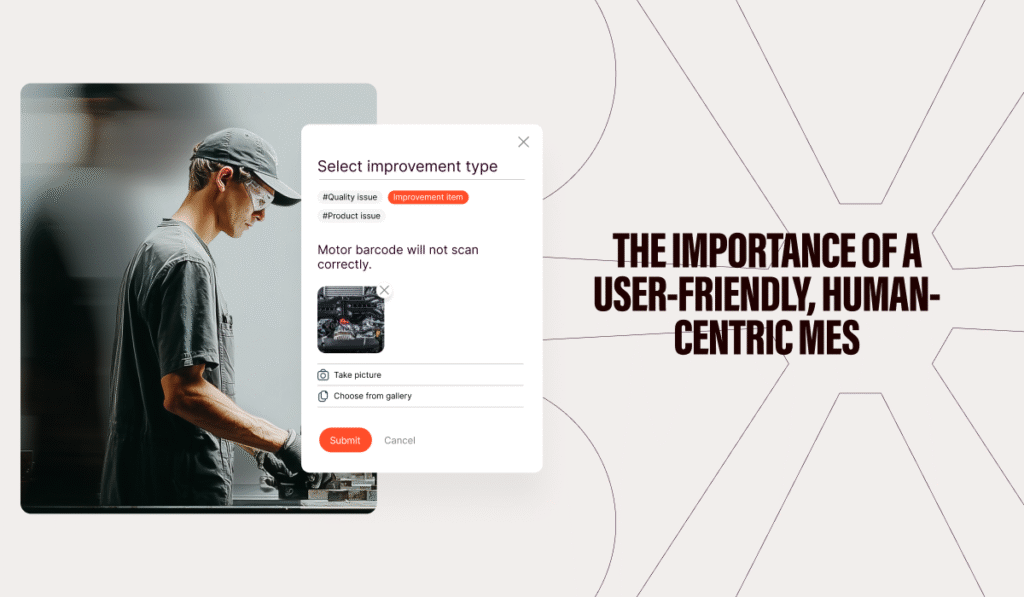

“Most manufacturing software is built for the C-suite, not the people on the floor. That’s backwards. Azumuta gets this and they’re starting where the actual work happens, building AI-rich software operators actually want to use. That’s why the product sticks and why tier-1 manufacturers rely on it every day.”

Fueling the Next Growth Phase

Recognized as one of Belgium’s fastest-growing technology companies and ranking 15th in the Deloitte Fast 50 Belgium, Azumuta is now entering a new growth phase. The company plans to expand its presence in key regions while reinforcing its Ghent base, strengthening relationships with customers, and advancing initiatives in innovation, product development, and customer success.

“Codifying how work gets done isn’t just solving today’s problems, it builds the foundation for tomorrow’s factory,” adds **Verwaayen**. “Whether that’s better tooling, smarter automation, or humans working alongside robots, you need that knowledge captured first. Azumuta’s helping manufacturers build that foundation while keeping their people at the center.

This Series A marks more than a financial milestone. It reinforces Azumuta’s mission to help manufacturers move faster, work smarter, and stay competitive in an increasingly digital, data-driven industry.

About Azumuta

Azumuta is a software scale-up that helps manufacturers worldwide turn frontline know-how into connected, AI-supported processes. Its modular platform brings operations, workers, and training together to boost operational efficiency, raise quality, and speed up training on shop floors.

Founded in 2016 and headquartered in Ghent, Belgium, Azumuta supports manufacturers of all sizes globally in bridging people and technology for the next generation of manufacturing.

And the name? It comes from the Japanese “始めた”, which translates to “I have started”, though locals in Ghent will tell you it also sounds a lot like “*ah zo moet da*”, dialect for “that’s how it’s done”.