The manufacturing industry is facing an undeniable shift. The aging workforce is a ticking clock, with a wave of experienced operators nearing retirement. This comes down to not only losing personnel, but also losing tribal knowledge. According to a 2025 McKinsey report, the share of U.S. manufacturing workers over 55 has more than doubled in the past two decades. As these so-called veterans leave, so does their intuitive understanding of machines, processes, and workarounds, which results in a brain drain of expertise that is difficult to replace and directly impacts productivity.

Meanwhile, technology on the shop floor is moving fast. Smarter machines, user-friendly interfaces, and digital systems are becoming the norm, bringing new opportunities, but also new demands. Today’s operators need more than hands-on mechanical skills; they’re expected to navigate digital tools, interpret production data, and keep up with constantly evolving processes. As automation takes on repetitive tasks, their role is shifting toward supervision, setup, and problem-solving. And that calls for a fresh approach to how we train and support operators.

This dual pressure of retiring experts and rising technical demands is widening the skills gap for many manufacturers. Add high turnover rates to the mix, and the challenge becomes even more acute. Building a stable, skilled team becomes harder when experience walks out faster than it can be replaced. On top of that, younger generations entering the workforce come with different expectations. They’re digital natives, eager for growth and meaning in their work, and less tolerant of working with outdated systems.

How to Empower Operators on the Shop Floor

Empowering operators requires deliberate effort to give them the right tools, opportunities, and confidence to excel. It means enabling them to take ownership of their work, grow their skills, and actively contribute to improvements. Several key strategies to achieve this on the shop floor.

1. Preserve What You Know, Before It Walks Out the Door

Every time a seasoned employee goes in retirement or leaves the company, decades of experience and tribal knowledge risk walking out with them. That kind of knowledge drain can be devastating, not just in lost expertise, but in real costs.

Replacing a skilled worker can cost $20,000 to $40,000 in recruiting and training, and many companies report that turnover is only getting worse. If that hard-earned know-how isn’t captured, the next generation of operators is forced to learn through mistakes and downtime rather than building on established best practices. And without measures in place to retain and transfer knowledge, manufacturers face higher costs, lower productivity, and a weaker operational efficiency.

Capture Tribal Knowledge

So, how can you preserve essential knowledge before it’s gone? The first step is to capture it. Encourage your seasoned operators to document tips, tricks, and process tweaks that they’ve learned over the years. Ditch the old three-ring binders gathering dust on a shelf, those static manuals can’t keep up with the complexity of modern production. Instead, consider creating a dynamic, connected knowledge base that everyone on the shop floor can access.

For example, using digital work instructions or mobile Standard Operating Procedures (SOPs) can turn expertise into step-by-step guides enriched with photos, videos, and annotations. These digital instructions preserve tribal knowledge by recording not just what to do, but how to do it in context, capturing details that might never make it into a paper manual. Operators can pull them up on a tablet or phone at their workstation, ensuring that the best practices are always at their fingertips.

Share Documentation

Just as important is keeping that knowledge up-to-date and accessible. Manufacturing know-how isn’t static; it evolves as materials, equipment, and processes change. A solution that worked last year might need tweaking today. By maintaining a real-time, central repository of procedures and lessons learned, you ensure that adjustments and improvements are continuously captured and shared. Modern digital platforms can integrate this knowledge capture into daily workflows, effectively transforming static documentation into a “living” knowledge system that guides decisions in real time.

For instance, when an operator finds a better way to set up a machine or notices a safety concern, they can update the instructions or log a note immediately. This turns every improvement or insight into institutional knowledge, preventing critical know-how from depending on any single person. In short, preserving knowledge through digital, accessible means empowers every operator, new or experienced, with the collective wisdom of your best people. It’s like having a senior team member look over everyone’s shoulder, guiding them to do the job right.

2. Empowering People Through Skills Development

The manufacturing skills gap is not closing on its own. As technology advances and processes grow more complex, the demand for skilled operators rises. Yet many manufacturers still struggle to find and keep qualified talent. One of the most effective ways to address this is by investing in continuous training and offering clear growth paths. When employees see that their development is a priority, they’re far more likely to stay.

But training can’t stop at onboarding or the occasional workshop. It needs to be part of the daily rhythm. This might mean pairing newer operators with veterans for hands-on mentorship, running regular workshops on lean practices or new equipment, or encouraging certifications and upskilling through short courses. A key enabler here is visibility: operators should be able to see where they stand and where they can grow.

That’s where a skill matrix, whether a basic chart or a digital dashboard, comes in. It maps out competencies, highlights gaps, and helps both managers and operators plan development in a structured, transparent way. Operators benefit too: they can track their progress, identify opportunities to level up, and see how to move into more advanced roles. For managers, it streamlines scheduling and ensures the right skills are always on shift.

Digital tools can take this further. Interactive work instructions that adjust to experience level, mobile training modules available on the shop floor, and automatic prompts for expiring certifications or new procedures, these are all ways to integrate learning into the flow of work. When skills development becomes a built-in part of the job, not an afterthought, you don’t just build a more capable workforce, you build one that’s ready for whatever comes next. Manufacturers who embed this approach see gains not just in performance, but in retention and adaptability.

3. Make Continuous Improvement Actually Happen on the Shop Floor

No one knows the ins and outs of a job better than the people who do it every day. To maintain a competitive edge, manufacturers need an environment where teams are encouraged to innovate and enhance operations at every turn. The people running the machines and assembling the products often have the keenest insights into inefficiencies and problems in the process. Empowering them to contribute has a direct impact on performance.

The first step is to give them a voice. Open communication should be encouraged, and feedback should be expected, not just tolerated. Whether it’s through daily stand-ups, suggestion programs, or informal channels, operators need clear opportunities to speak up. Just as importantly, leaders must close the loop: act on the feedback when possible, and explain decisions when action isn’t taken. Nothing erodes motivation faster than feeling unheard.

On the other hand, when operators see their ideas lead to real changes, even small ones like a smoother task flow or a minor safety fix, it builds ownership. Studies have shown that employees who feel their voice is heard are nearly 4.6 times more likely to perform their best work. That’s a huge boost to productivity and quality, simply from listening and responding to your team’s ideas.

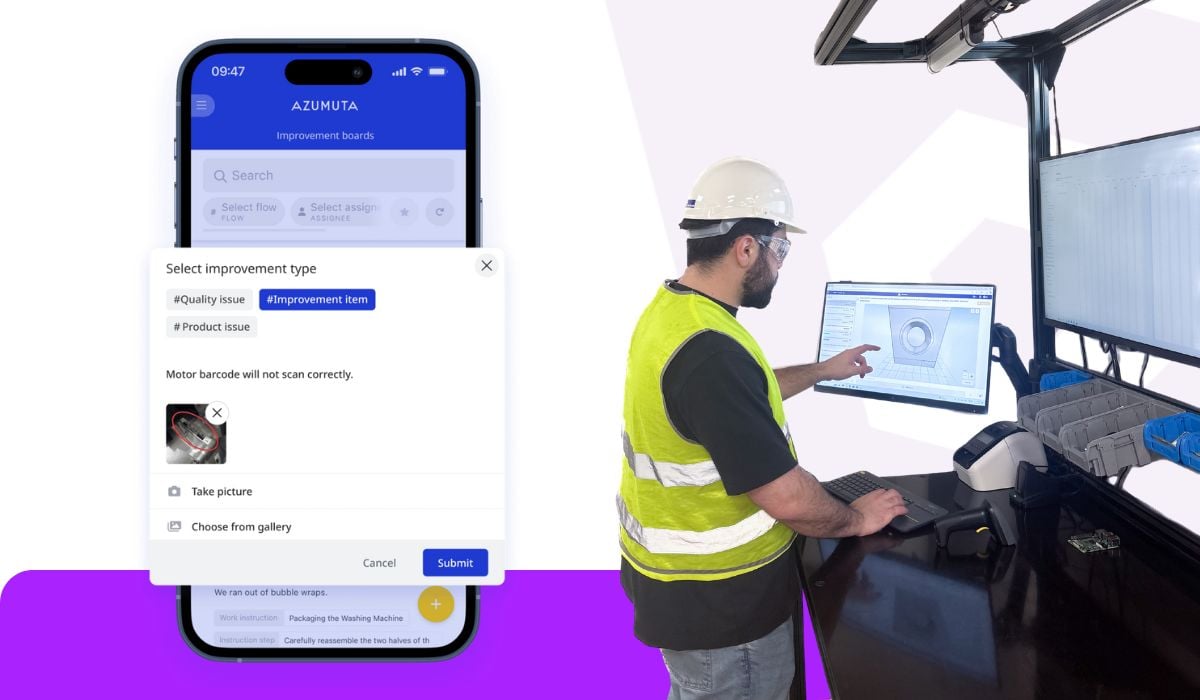

Modern technology can support a culture of continuous improvement by making feedback and problem-solving instantaneous. For example, some digital platforms let operators flag a quality issue or log an improvement idea right on the spot, via a tablet or kiosk. Think about an assembly operator encountering a fit issue with a part, instead of working around it silently, they could snap a photo, annotate it, and submit it as a ticket for investigation. This kind of real-time documentation and communication ensures no good idea or critical observation is lost. It also enables managers to identify patterns (e.g. if multiple operators flag the same recurring issue, you know where to focus your next process improvement effort).

Over time, this creates a loop where frontline workers and management are in constant dialogue about how to do things better. This way, continuous improvement ceases to be just a slogan on a poster and becomes a daily practice embedded in the workflow.

The Future of Manufacturing Is Human-Centric

Replacing the human workforce by machines and robotics isn’t the way to solve the manufacturing challenges that lie ahead. They demand operators who are confident decision-makers, skilled problem-solvers, and trusted keepers of process knowledge. Empowering employees is more than an HR initiative, it’s the foundation of a resilient, future-ready operation.

When operators have the tools to access to the information they need, the training to grow their skills, and a feedback loop that actually closes, they’ll feel empowered. This means pairing human expertise with digital tools that make knowledge easy to capture, share, and access in the moment it’s needed. It means creating clear skill roadmaps so employees see exactly how they can advance. And it means fostering a culture where suggestions from the floor are heard, acted upon, and celebrated. The result is higher productivity, sharper decision-making, and greater job satisfaction.

Technology will keep evolving, but it’s the people who adapt it, refine it, and make it work in real production environments. The best operations are those where the human element and the digital infrastructure work hand in hand, where automation handles the repetitive, and operators focus on improvement.

Create Your First Work Instruction

Try Azumuta today and see how easy it is to create and share work instructions for your manufacturing process.